What Are The Best Gm Connecting Rod Bearing For The Money

Information technology tin be a very tortuous existence for engine bearings. Call back about information technology. Bearings are at that place to be abused and many engine builders treat them equally a consumable. Most of the attending bearings receive is heaped upon design, clearances, and oil feed theory. Merely once the engine is broken-in and running, attention shifts to other concerns.

This story looks at how bearings, coatings, and the oil you choose tin accept a dramatic result on bearing life. As you might expect, this means spending a picayune more than coin up front, but the results may make that an like shooting fish in a barrel decision.

The engineers at King Bearings — headed past Dr. Dmitri Kopeliovich, a leading adept in design, engineering science and materials for engine bearings — have recently adult a new performance rod and main bearing called the pMaxBlack. This is a begetting with major changes to the tri-metal blend, in a quest to create a cloth that is still soft plenty to handle a high-output engine, while simultaneously offer increased fatigue resistance and load carrying capacity. The inside story on how King developed this begetting is steeped in alloy-metal technology, so allow's only say they figured out a way to make a begetting stronger to withstand the abuse from increased ability levels while still making information technology soft enough to properly exercise its chore.

Begetting Theory

Race or performance oriented tri-metal bearings are built intentionally soft considering, if a rod periodical deflects or a crankshaft bends under loftier load, the periodical may contact the bearing. If the bearing is soft plenty, it but wears slightly. Unfortunately, common cold startups tend to take their toll on engine bearings, since the creepo rotates for several revolutions before the motion picture of oil builds upwards betwixt the bearing and the journal. This is why you frequently see race teams pressure lube the engine each time before cold startup.

The King pMaxBlack performance bearing isn't a coating but rather a new bearing meridian overlay that increases hardness by 24-per centum yet with 17-percent greater fatigue resistance. Adding the pMax Kote blanket makes these bearings fifty-fifty more habiliment-resistant.

King 's aluminum-alloy bearing cloth (HP prefix) is used in very high-load applications. According to Ron Sledge of King Bearings, "The elapsing of fourth dimension of the loading is what separates which bearing to utilize, HP vs. XP or XPC. The HP will handle very loftier loading for a shorter catamenia of time (like drag racing) whereas the XP or XPC will handle very high loading for longer fourth dimension periods, like circle-track and off-road racing."

"The advantage of the HP bearing is that it will tolerate treatment debris and crankshaft deflection better than the XP or XPC because of the 0.012-inch thickness of the aluminum layer." The babbit overlay on the XP bearing is only 0.0005-inch thick. This thinner layer does not tolerate debris and crankshaft deflection as well.

Bearing Hardness

| Bearing MATERIAL | HARDNESS RATING |

| Aluminum | xl Hv |

| Tri-metal | 11-14 Hv |

| pMaxBlack | 18 Hv |

| pMaxKote | xl Hv |

Keeping Up With Technology

Today's 21st-century street engines are at present making more horsepower than pure contest engines from every bit footling as two decades agone. Builders naturally expect the bearings to keep up with these enhanced power plateaus. This is why Rex Bearings developed the pMax Black bearings.

Taking this idea a step further, King adult a coating for this bearing called pMaxKote. This becomes the ultimate-performance King bearing, employing what the company calls a nano-composite polymer blanket. According to Sledge, the term nano-blended just ways it is made upward of nanosized materials in a polymer base. The coating is added on acme of the pMaxBlack overlay and does non increase the thickness of the overall bearing wall.

To maintain the same dimensions, King compensates with the thickness of the intermediate copper layer to allow for the 0.0002-inch thickness of the pMaxBlack coating. This allows for maintaining the same oil clearances as uncoated counterparts. The blanket protects the begetting from mild abuse and is designed to be extremely wear resistant – even when slight contact is fabricated with the crankshaft.

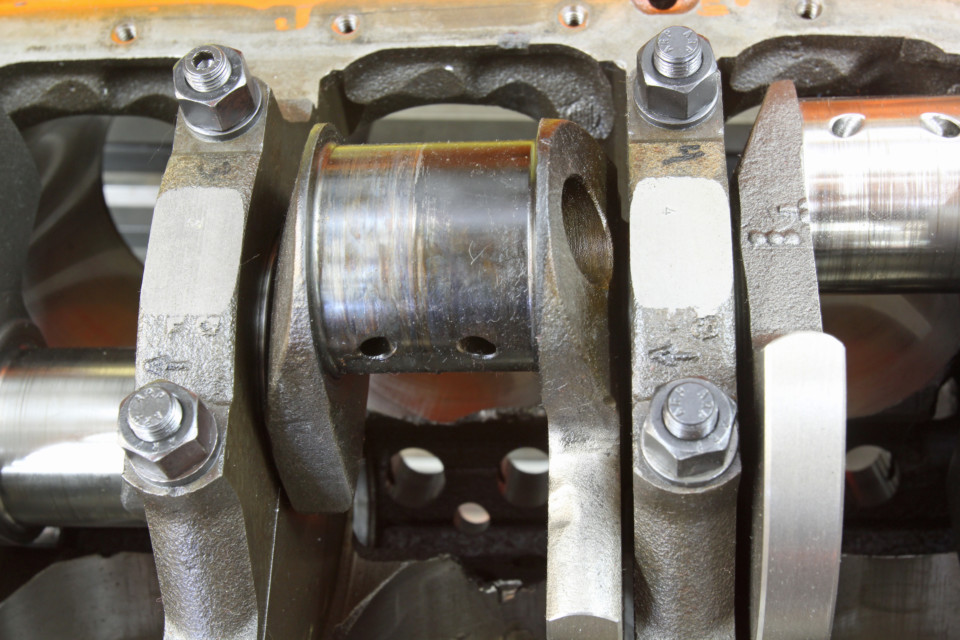

This is what happens when a connecting rod bearing runs for a curt time at max load with insufficient lubrication. Connecting rod bearings often fail starting time because they are heavily loaded and are last in line for lubrication.

Put To The Examination

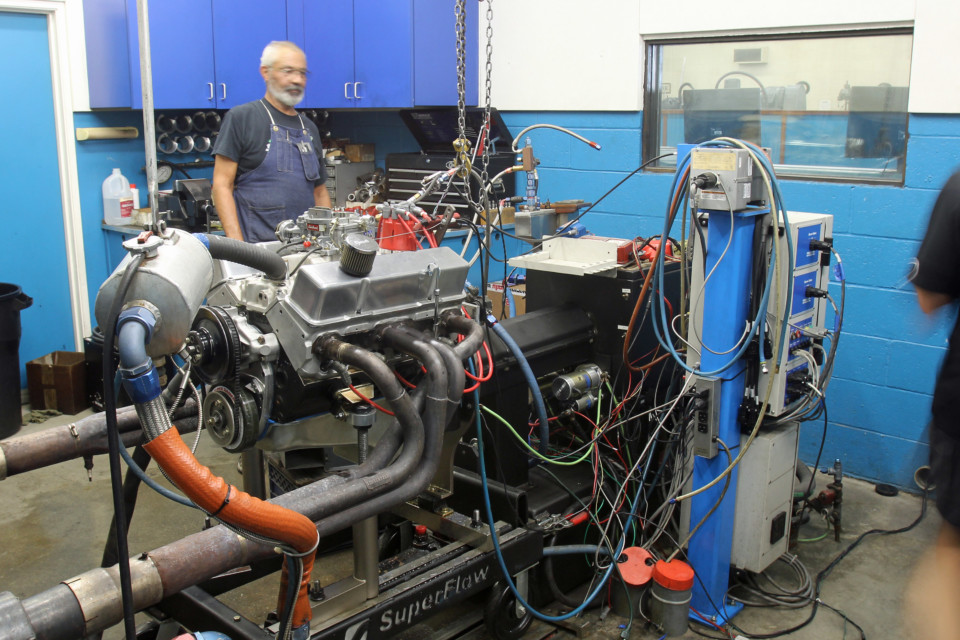

All of this sounds actually good, merely the question becomes, how would this coating work in the real world of internal combustion engines? Rex idea that an independent examination would be a skillful idea, so they collaborated with Lake Speed, Jr. at Driven Racing Oils, and the team at Shaver Specialties, where they prepare an abusive test schedule. The plan took shape by placing a relatively mild 440 hp, 383ci small-block Chevy on the dyno. They used a purposely excessive cylinder test authorities that would heap serious load on the connecting rod and primary bearings and then evaluate the results.

This required a baseline or command combination, with a couple sets of Rex XP, Tri-metallic bearings, and Driven supplied a mineral-based, 5W-20 equally the baseline lubricant. To brand this a true lubricant comparison, the engine oil condiment packages had to be exactly the same. Because there were no off-the-shelf mineral-based and synthetics with the same exact condiment package, Speed supplied both custom-blended oils for the exam.

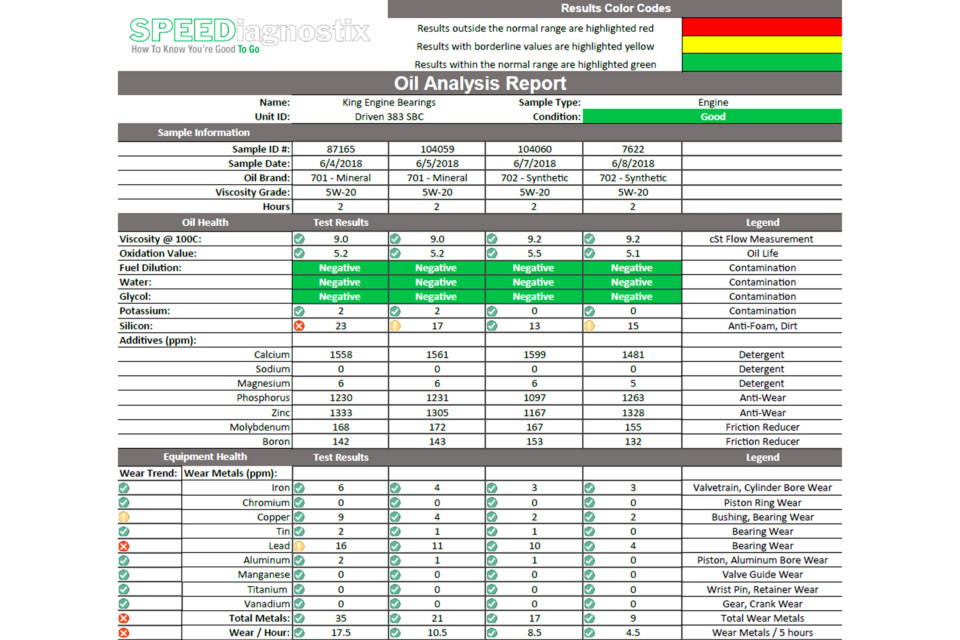

This is an example SPEEDiagnostix report sheet from this exam. It shows the blazon of results you lot can wait as part of the evaluation. Any alert signs are immediately highlighted in xanthous or red. If everything is good, the check marks are in dark-green.

Neither is bachelor as an off-the-shelf oil with this specific blend of additives, merely they both are representative of loftier-zinc and high-phosphorus lubricants. Speed chose a lower viscosity base-oil which would intentionally decrease the oil film thickness and increment potential bearing contact and habiliment.

Every bit you can encounter from the results chart, the differences are measured in as lilliputian every bit single-digit parts-per-1000000 (ppm) numbers. In lodge to ensure these numbers are accurate, Speed also performed a flush procedure betwixt each of the 4 tests. This involves draining the exam oil, removing the Wix oil filter, and refilling with Driven's break-in oil BR30 along with a new filter, and then running the engine for 30 minutes, including ii total-power dyno runs. So the break-in oil is drained and the filter removed and the next oil is added. This exact same procedure is repeated when the bearings are changed. This ensures that the results will be every bit accurate as possible.

This photo shows the uncoated XP rod bearing on the right after running loaded for over three hours using a 5w20 conventional oil. The same test with the same oil was performed on the King pMaxBlack XP begetting on the left. The wear reduction is obvious.

The accompanying results nautical chart also lists the additive package. Zinc and phosphorus (ZDDP) are anti-wear additives that most enthusiasts are familiar with. Molybdenum and boron are friction-reducing additives while calcium is employed every bit a detergent. These were the main additive package ingredients for both the conventional and the synthetic oils so that the merely deviation was the base oil.

After the first exam sequence with the petroleum-based oil, Shavers' engine architect, Keith Chrisco, removed the first set of bearings and added a second ready of identical XP bearings. He then ran the engine using the mPAO-based synthetic 5w20 oil.

The third test involved switching to a new ready of King'southward pMaxKote rod and main bearings, but returning to the traditional mineral base 5w20 oil. The fourth and final test saw the installation of another new set of pMaxKote bearings run this time with the synthetic oil. This created a comparison of coated and non-coated bearings with traditional and synthetic engine oil.

These are five of the lower, uncoated XP bearings equally they were pulled straight from the engine after running the test using conventional oil. Equally you can encounter, there is considerable vesture.

The evaluation benchmark for each test would be a comparing of the clothing count of the different metals (in ppm) past analyzing the oil drained from each test. The testing was performed by SPEEDiagnostix, a new oil evaluation company using the same metal spectrometer techniques as is used in current Formula i racing.

The best manner to actually load these bearings and ensure that the test schedule would be both consistent and survivable was to pull the aforementioned pocket-sized-cake Chevy downwardly to an extremely low RPM with a high load. The SuperFlow dyno was able to pull this footling Chevy down to 1,450 rpm for a total of iii hours and fifteen minutes for each of the four tests. During this fourth dimension, the depression-RPM test was interrupted so the engine could also be subjected to a complete test up to only by peak horsepower a total of 14 times. Oil and water temperature was also closely monitored.

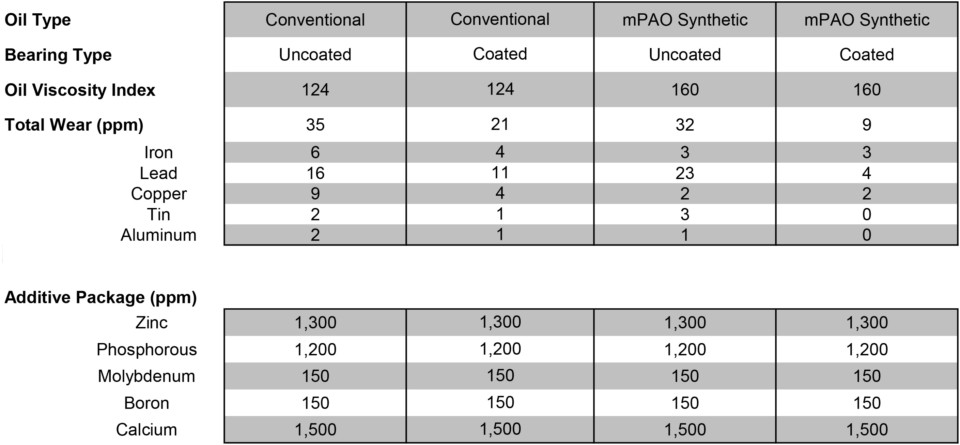

Instead of horsepower, this test was all about survivability. In the attached nautical chart, we have condensed a much more than expansive report down to the clothing results. The of import wear materials are fe, copper, pb, can, and aluminum. Both the standard and coated Rex tri-metallic bearings are fabricated up mainly of copper, tin, and lead so these would be the major elements that would point begetting wear. Aluminum would originate mainly from the pistons while the iron would probable be sourced from the cylinder walls.

While the trace material numbers are relatively depression PPM counts, it is the differences from each test that is compelling. Permit's start by explaining each category in the results sheet. The Oil Blazon indicates the type of oil – either conventional or synthetic. The Begetting Type indicates whether the bearings were coated or uncoated. The Oil Viscosity Index is a rating system applied to engine oil that indicates how much an oil viscosity changes over a wide temperature range. The higher the number, the more thermally stable the oil is over a wide range of temperature. This means that equally the oil warms up, it loses less viscosity.

This bearing and oil exam demanded the engine be subjected to multiple tear-downs to supervene upon all the bearings but the results were well worth the effort. Shavers' small-cake has been torn down so many times information technology should have zippers. To save fourth dimension, Chrisco inverse the primary bearings without pulling the crank. He loosened all the main caps and carefully removed the erstwhile bearings and installed the new ones by pushing the bearing while turning the crank.

Likewise note, that we've listed each additive component in ppm. This is important because this conspicuously shows that the additive packages for both the conventional and the synthetic oils were identical. Then this means that any reduction in wear materials (when comparing oil) must be attributed to the quality of the base of operations oil and not to the additive package.

Now that we've got that handled, the results betoken that the combination of King Bearings' MaxKote begetting with an mPAO synthetic base oil is an excellent way to drastically reduce wear in an engine. As you tin see, the baseline total wear number of 35 ppm (created only past calculation upward the wear numbers of each individual element) using a conventional bearing and a mineral-based oil, was reduced 74-percent past using a high-quality mPAO synthetic like that from Driven Racing Oil, combined with the pMaxKote bearings.

Merely irresolute to the coated bearings while retaining the conventional oil also produced a significant comeback, reducing the overall total habiliment count from 36 to 21 ppm, which is a twoscore-percent improvement in wear. This reveals the significant increase in durability from the coating itself. This is specially important when you become into a cost-performance ratio because the coated King bearings are more than expensive compared to non-coated rod bearings for a small-block Chevy.

You will note in the results a somewhat higher-than-predictable atomic number 82 wear metal reading in the third test with an uncoated bearing and the constructed base oil. The lead is the dominant metal constitute in a tri-metal bearing overlay (lead babbit), so wear was slightly college in this example compared to the conventional oil. While every try was made to keep the testing as standardized as possible, in that location are any number of variables that could account for this higher number. While the lead numbers were college than whatever other exam, the full habiliment metal count was however lower than uncoated bearings with conventional oil.

Shavers' 383ci small-block Chevy has been horribly abused over dozens of dyno tests over several years and is however going strong.

While the constructed oil used in this test was a custom blend to standardize the additive packages, Speed said that a Driven oil that would exist comparable to the mPAO constructed used in this test would be Driven'south XP line of race oils. These are available in several different viscosities based on how the engine would be used, ranging from a 0W to a 15w-fifty. This oil is more expensive, simply when y'all consider the expense involved with rebuilding an engine, the cost is easily justified, considering the oil will last so much longer with lower wear metallic contamination.

Engine habiliment isn't something that most hot rodders stress over, simply with the sizable investment that most engines demand, perchance it is a subject field that should be given its fair share of attention.

Condensed Test Results

Source: https://www.enginelabs.com/engine-tech/the-secret-life-of-bearings-a-test-of-bearing-and-oil-wear-rates/

Posted by: mclaughlinwhight.blogspot.com

0 Response to "What Are The Best Gm Connecting Rod Bearing For The Money"

Post a Comment